Three Metals, One Shot: Bronze XT Now Available – Part 3

Bronze XT is now available on my online store in 100-gram and 50-gram jars.

Very Good News:

Since my last posting I have been making the same pieces over and over. As it turned out, the part of my earlier posting that warns about a “bleeding” reaction between copper and Bronze XT at the high-fire schedule was a false alarm. I had observed this behavior in a kiln that turns out to have been over-firing due to wear. My new experiments were repeated in a kiln with a new thermocouple and elements. No bleeding reaction between copper and Bronze XT has occurred ever since then.

The reaction between copper and Bronze XT at the high-fire schedule is the same as the reaction between copper and regular bronze at the mid-fire schedule; there is some reaction but it is predictable and can be accounted for. You can read all about in in my book Patterns of Color in Metal Clay, pp. 8 and 12.

Please note the following change in the instruction manual and my earlier blog posing, entitled “Bronze XT – Part 1“:

The part that discusses the reaction between copper and Bronze XT (p. 13 in the instruction manual), has now been deleted from the instruction manual. The corresponding part in the “Bronze XT – Part 1″ blog posting has now been stricken out.

So, there is no reason to separate copper from Bronze XT using empty space or steel!

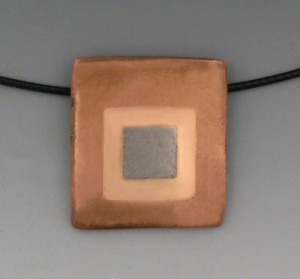

I went back to some of my old pieces and made them again in three metals.

This latter piece I had made twice before: once with copper and silver, and once in bronze and silver. In both cases I had to fire the base metal first, then add the silver part using the “hot riveting” and “wraparound” techniques and fire a second time. It’s unbelievable how easy it was to make it this time – like working with a single metal.

You may have noticed that I chose copper for a backing layer in all the pieces that were displayed in the three parts of this article. The reason is that copper is the one which shrinks the least. If Bronze XT or steel were chosen as a backing layer, they would shrink more than the overlay parts, and would either bend backwards or crack. This has always been my choice, even when I used a combination of copper and regular bronze. For now it seems that this is the safe way to go.

I am releasing Bronze XT now with a strong feeling that there is a solid base of resolved issues to lean on. I am going back to working on my book now, to incorporate projects for mixed metals with Bronze XT. I would love to include work of yours that will have been made with this new clay!

May 10th, 2012 at 9:07 pm

This is great Hadar!!!! I can’t wait to start playing with Bronze XT :). Are you still looking for examples of mirror image earrings for your book?? Are there any other pieces you would like us to send you? If so, when do you need the submissions by?? Thanks so much!!!! 🙂

Kelly

May 11th, 2012 at 4:26 am

Thanks Hadar. Does that mean the new Bronze XT can be used for mokume gane?

May 11th, 2012 at 9:00 am

Linda, This is an aesthetic choice. If you like a more subtle contrast, as in the photos at the end of part 1 of the blog posting, then yes, you can. If you want sharper contrast then regular bronze at mid-fire schedule is a better choice.

May 11th, 2012 at 9:02 am

Kelly, Absolutely, send whatever you have. Try to make it by the end of July.

May 14th, 2012 at 5:21 pm

These are beautiful and I am so looking forward to trying it.

Thank you Hadar!

ann