New Ways of Working with White Bronze

White Bronze combines beautifully with other metal clays. Because of its low firing temperature I used to think that in order to do this, you had to fire the other metal first, then add White Bronze using a mechanical connection, and re-fire at the lower temperature. For example:

In the two pieces above (the ring is Friendly Brilliant Bronze and the earrings are Friendly Copper), the White Bronze is connected to itself around a tube. This is a mechanical connection and it is hard to tell if the White Bronze is actually fused to the other metals.

Recent experiments show that it actually is fused to them. The result is strong, non-brittle pieces, with two strong advantages:

- It’s hard to distinguish White Bronze color from silver

- White Bronze tarnishes less than any other metal, including silver

I fired pieces of bronze and copper first and just placed a layer of unfired White Bronze on top of each, with no mechanical connection. I always thought that there wasn’t enough pressure to make these two layers fuse. I was proven wrong! Here are some examples:

Full overlay of of White Bronze on Friendly Brilliant Bronze:

Full overlay of White Bronze over Friendly Copper:

Partial overlay of White Bronze on Friendly Copper:

In the following example only the White Bronze shows on the front of the piece; the backing is Friendly Brilliant Bronze:

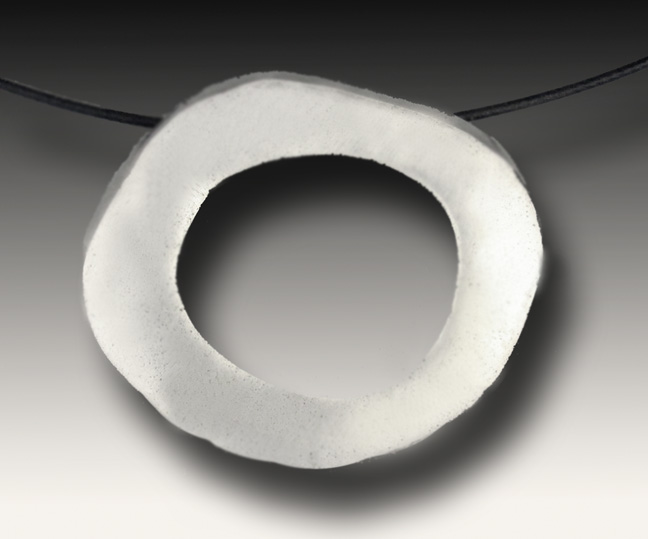

What about hollow forms? This pendant and donut were constructed with Friendly Brilliant Bronze. The fired pieces were fired and covered with White Bronze, then fired again.

And these earring are two-sided; only one side was covered with White Bronze:

So far, applying White Bronze to another metal with no mechanical connection works with all other clays except for steels (these will require a mechanical connection.

The Process

- The backing layer (in a flat piece) or the core (in a hollow form) is 3-cards thick.

- Fire the pieces to the maximum temperature required for the specific clay. If distortion occurs, hammer or bend the pieces into shape.

- Add a 3-card layer of White Bronze. Make sure the White Bronze is connected to the fired metal at every point of its surface area.

- This is important: Let the the White Bronze overlay dry naturally or it will come off the backing layer. If you need to remove it in order to file or sand holes, as in the earrings shown above, wet the back of the overlay and press it into the backing layer. Then let it dry naturally. The White Bronze layer should be well bonded with the backing layer before going into the kiln.

- Fire for 2 hours at 1330°F in a brick kiln, 1380°F in a muffle kiln.

(True, this temperature is way higher than the firing temperature of White Bronze alone. However, bear in mind that the first metal used acts like a heat sink; it draws the heat away from the White Bronze, and this is why it is not over-fired.)

A few more interesting results:

The core of this hollow form is Friendly Brilliant Bronze. Two sides of the forms are covered with White Bronze, and the third side with a mokume gane layer of White Bronze and Pearl Grey Steel. It seems that this tricky combination is facilitated by the bronze backing.

And this one is still experimental: it is a solid piece of mokume gane made with Friendly Copper and White Bronze, with no backing layer or core.

March 23rd, 2015 at 11:46 am

Very cool! On my to-do list. Thank you

March 23rd, 2015 at 12:40 pm

Couldn’t White Satin be used instead of White Bronze in each of the above combinations? How would the results differ?

March 23rd, 2015 at 1:38 pm

Ron, White Satin fires higher than bronze. So you can fire White Satin first and add bronze, but not the other way around. As for copper, it can be used this way, but it’s not necessary, since you can combine the two in one firing only.

March 23rd, 2015 at 5:03 pm

Oh, Hadar, how can I possibly keep up? Too many interesting things. Do either the White Satin or White Bronze contain nickel? I am allergic and don’t want to work with any nickel. I think you said no, but I wanted to double check.

March 23rd, 2015 at 5:31 pm

Thank you. I was just wondering whether one could use white bronze with a bronze backing for strength. From your photos the white bronze doesn’t appear to shrink much, might shrinkage be a problem? I have painted white bronze slip on fired bronze for little ‘highlights’, the beak and claws on a bronze eagle pendant and it worked very well.

March 24th, 2015 at 6:22 am

I was also wondering about nickel in clays. Would be great to know which ones are nickel-free.

March 25th, 2015 at 9:57 am

Wonderful work Hadar. Does the prefired base need to be polished before adding the overlay?

March 25th, 2015 at 7:22 pm

Hi Corinne, None of my clays contains nickel.

March 25th, 2015 at 7:23 pm

Joan, It’s true that White Bronze doesn’t shrink so much. I had no distortions whatsoever.

March 25th, 2015 at 7:23 pm

Elena, All my clays are nickel-free.

March 25th, 2015 at 7:24 pm

Cindy, There is no need to polish the backing layer.

May 25th, 2015 at 10:27 pm

Hello…Is there any special prep you need to do (or not do) to either the backing surface or the overlay? It sounded like you only wet the overlay in specific cases?