Hadar’s Molds – A Project for Two Molds

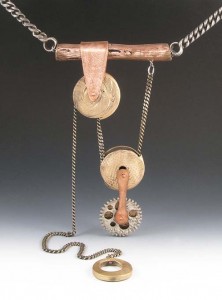

As promised, here is the first of a few projects demonstrating some of what you can do with Hadar’s molds. The piece in the photo below is a concave pendant made with Rose Bronze.

I used two molds for this piece: Mokume-Gane 2 and Tree Bark.

You will need a concave area to dry the clay on. You can use a small bowl or a sapping die. I like to use plastic fondant mold. They come in various sizes, and they are cheap and available from Michael’s and JoAnn Fabrics.

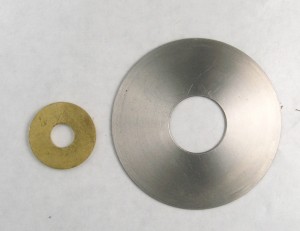

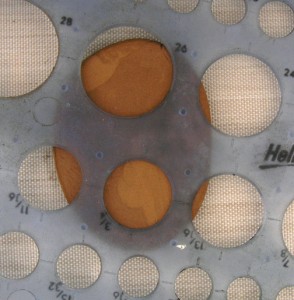

1. Roll a layer of clay 4 cards thick. Pick a circle, more or less the same size as the Mokume-Gane 2 mold, and cut a circle out of the layer. Lay it in the concave area. It is recommended to dry it at least halfway before continuing. You can dry it in the air, in a vegetable dehydrator, or with a hair dryer, but not on a warming pan, because the plastic will melt.

2. Once the base layer is dry or almost dry, roll a layer of clay, 8 cards thick, and press it well into into the Mokume-Gane 2 mold to get a good impression. As you press it, it will become thinner.

3. Cut a rectangle out of the center of the mold. Lay it on the backing layer, in the center or off center.

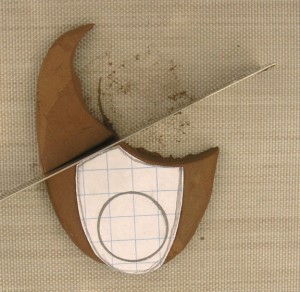

4. Roll a layer textured with the Tree Bark mold. If you like, make it with a different metal. It does not have to be the same thickness as the center piece, but don’t make it thicker, since that would make it hard to reach the center piece for finishing after firing.

5. With a tissue blade, cut a vertical line on the left side of the layer.

As you can see in the photo, I used the mold called Crater, but I changed my mind because it seemed to be competing with the main texture.

6. Wet the backing layer and lay the layer adjacent to the mokume-gane rectangle.

7. With a knife, cut away the excess clay from the layer; let the dry backing layer lead your knife. The water will make the layer stay put and not move while you are cutting.

8. Repeat steps 4-7 with the left side of the rectangle. This time, cut a vertical line on the right side of the layer (step 5) and lay in the left side of the rectangle (step 6).

9. Dry the piece completely. You can remove it from the concave area and place it face down on the heating pan.

10. Fill the gapes between the backing layer and the overlays with clay. Dry again.

11. Make a bail on the back of the pendant. You can find a suggestion for a certain type of bail in my book The Handbook of Metal Clay: Textures and Forms, second edition, p. 36.

12. Fire the piece using the firing schedule appropriate for the clay that you used (see Instruction Manual for Hadar’s Clay from September 26, 2013.

13. Since this piece is textured, finishing is relatively easy. Use radial discs to clean the Tree Bark texture. For a good contrast, you can sand the mokume-gane rectangle, first with 220-grit sandpaper, then with 400 grit. See more information on finishing in the document entitled “Finishing Fired Metal Clay” on my blog.